Did you know that digital twins are on the verge of becoming a worldwide trend? Studies indicate remarkable growth in funding for the digital twin market, with estimates reaching $131.09 billion by 2030, compared to a mere $6.30 billion in 2021.

The global era of digital twins will probably arrive soon, leading to many companies embracing this innovative technology for their development and advancement.

In this article, we’ll delve deeper into the world of digital twins and explore their diverse applications across industries. We’ll discover how technology assists in product development, prevent equipment breakdowns, enhance city infrastructure management, and even advance healthcare. Additionally, we’ll examine the challenges associated with this technology and its potential for further development.

The central concept of the digital twin technology

So, let’s begin with the basics. First, we need to understand the general concept of the technology.

A digital twin is a virtual model that accurately represents a physical object. The physical object must be equipped with sensors that collect the necessary information. You need to transfer this information to a digital copy, analyze and apply it to the digital twin.

Thus, you gain the opportunity to simulate various scenarios in the digital realm, enabling you to study issues and gather valuable insights for the corresponding physical object.

The idea of digital twins belongs to David Gelerneter, who introduced it in 1991 through his publication ‘Mirror Worlds’. However, the practical application of digital twins didn’t occur until 2002.

Dr. Michael Greaves, a professor at the University of Michigan, pioneered using digital twins in manufacturing and proposed the software concept for this emerging technology.

The term ‘digital twin’ was coined in 2010 by John Vickers, an employee at NASA.

By the way, NASA researchers are associated with the early development of digital twins, as they were among the first to explore using a digital twin as a tool for studying physical objects. In the 1960s, they created accurate reproductions of spacecraft to allow the crew to analyze and simulate space scenarios. Although such early versions of digital twins may not fully align with the modern definition, NASA’s approach embodied the fundamental idea of a digital twin.

You might think: in the good old days, we called this technology simulation. But in fact, these are pretty different concepts for several reasons:

- Enriched Exploration. Digital twins offer a much richer exploration experience, encompassing an entirely virtual environment. It represents the primary distinction between a digital twin and a simulation scale. A simulation typically focuses on a specific process, whereas a virtual twin can learn multiple processes by running infinite simulations.

- Real-Time Insights. Simulations typically don’t require real-time data updates. In contrast, digital twins are designed explicitly with two-way communication in mind. Sensors collect information from the physical object, which is then processed by the system, and the insights generated by the processor are fed back to the original thing. As a result, the real-time mode is more relevant and beneficial for digital twins, as it enables immediate and ongoing interaction between the virtual model and the physical counterpart.

- Expanded Potential. Digital twins can explore a broader range of problems and incorporate multiple perspectives compared to standard simulations. As a result, the potential of this technology surpasses that of traditional simulations.

Digital twins generally represent a broader and more versatile technology than simulations. Furthermore, various types of digital twins can be particularly advantageous in specific domains. Let’s delve deeper into the classification of these technologies.

Types of digital twins

The differentiation among digital twins stems from their applications in domains. When selecting a specific technology, it’s essential to consider the scale of your product. However, it’s worth noting that multiple types of digital twins can also be employed for the same physical object. Let’s discuss the types further.

A Component Twin

This type of digital twin that specifically focuses on creating a virtual representation of individual components or parts of an object. For instance, a Component Twin could represent a particular engine or equipment in industrial settings. Digital twins of components enable the monitoring of the status and performance of each component individually.A Process Twin

It is a digital twin that involves creating a model and simulating a specific process. For instance, a process digital twin can be utilized to visualize and analyze manufacturing processes, logistics operations, or supply chain management. It plays a crucial role in optimizing and enhancing functions, identifying bottlenecks, and predicting the outcomes of process modifications. Businesses can make informed decisions to improve efficiency and productivity by leveraging a process twin.A System Twin

This digital twin integrates an entire system’s components and processes. The digital twin of a system aids in modeling and analyzing the interactions among various elements within the system, optimizing their collective functioning. Examples of system twins include digital twins of power supply systems, transportation networks, and smart cities. By employing a system twin, organizations can gain insights into the overall performance of complex systems, identify areas for improvement, and enhance their overall efficiency.

Each of these types of digital twins has its own unique applications and provides valuable insights for improving productivity, streamlining processes, and decision-making across industries. We will further discuss the areas and reasons why digital twins are used.

Top 6 reasons to use digital twins for business

Businesses choose the digital twin approach for several reasons, as it offers numerous benefits and applications across industries. Here are some of the reasons why companies select digital twins:

- Improved performance and efficiency. Digital twins provide real-time information about the performance and behavior of physical assets or systems. By monitoring and analyzing data from the digital twin, businesses can identify gaps, optimize processes, and make informed decisions to improve overall productivity and efficiency.

- Predictive maintenance. Digital twins provide predictive maintenance that helps companies detect and fix potential problems before they lead to costly breakdowns or failures. By continuously monitoring the health and performance of assets with a digital twin, businesses can proactively plan for maintenance, reduce downtime and extend equipment life.

- Modeling and testing. Digital twins allow enterprises to virtually simulate and test scenarios without physical prototypes or actual experiments. This capability is precious for product development, process optimization, and risk analysis. It allows enterprises to explore configurations and make data-driven decisions before deploying them to the physical world.

- Remote monitoring and control. With digital twins, businesses can remotely track and control assets or systems anywhere. This capability is beneficial for managing assets in remote or dangerous environments, improving security, and optimizing resource allocation. It also facilitates remote troubleshooting, reducing the need for field trips and minimizing operating costs.

- Training and modeling. Digital twins serve as valuable learning tools. It allows employees to gain hands-on experience and practice operating complex equipment or systems in a secure virtual environment. Technology promotes skill development, reduces training costs, and improves overall operational readiness.

- Life cycle management. Digital twins provide an end-to-end view of an asset or system throughout its life cycle. This perspective allows businesses to optimize asset utilization, plan upgrades or replacements, and ensure compliance.

Another reason why digital twins are gaining popularity is the ever-evolving Internet of Things (IoT). IoT devices are integral to this technology, and their development enables the creation of new scenarios. Thanks to the Internet of Things, it’s easier to transmit information in real-time, manage digital twins, and monitor the current situation. In general, IoT is one of the best ways to connect the digital and real worlds, significantly facilitating technology use.

In general, companies are using the digital twin approach to:

- improve operational efficiency

- reduce costs

- minimize risk

- drive innovation across industries, including manufacturing, energy, healthcare, transportation, and smart cities.

Through real-time simulation, businesses can make better decisions, optimize processes, and offer better products and services. But are digital twins really that great?

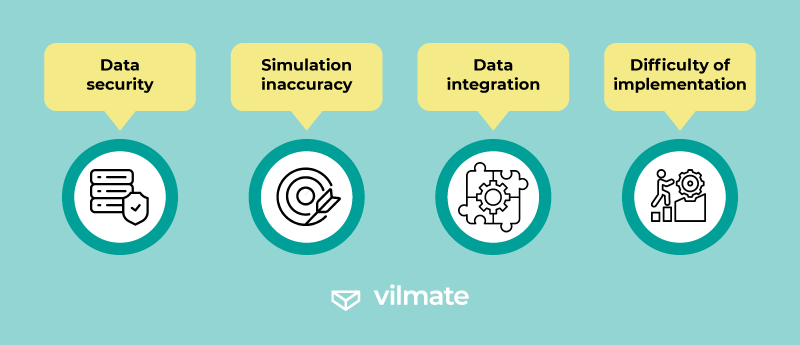

Risks of using digital twins

The advantages of digital twins are many, but we must not forget about the risks:

- Data security. Digital twins collect and process large amounts of data, including confidential information about the enterprise, processes, and assets. There is a risk of unauthorized access, data leakage, or cyberattacks that can lead to loss of confidentiality and negative consequences for the enterprise.

- Simulation inaccuracy. Digital twins are based on models representing an enterprise’s physical systems and processes. Inaccuracies in models or lack of precision in data can lead to incorrect conclusions and erroneous decisions.

- Data integration. The creation of digital twins requires the integration of data from various sources and enterprise systems. Low quality or data inconsistency can lead to distorted results and incorrect conclusions.

- Difficulty of implementation. Implementing and deploying digital twins can be complex and require significant financial and technical resources. Adapting existing systems and processes of the enterprise can cause problems and require additional staff training.

As technology continues to develop, the risks become less pronounced for enterprises. Consequently, numerous global companies are already leveraging digital twins for their purposes. Let’s explore the various areas where this technology is applied and examine successful case studies of its utilization.

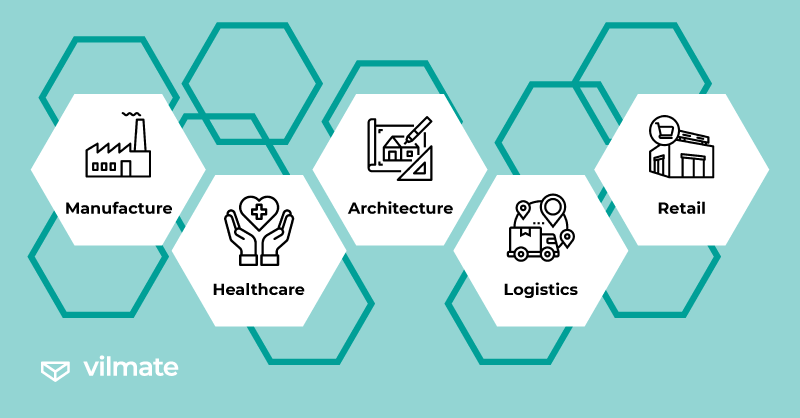

Which industries are the most interested in digital twins?

So, let’s look at 5 main areas in which digital twins will be indispensable in the near future.

1. Manufacture

Manufacturing stands out as the primary application for digital twins, with many experts suggesting it will lead to a new industrial revolution known as Industry 4.0. This notion’s enthusiasm stems from the expanded capabilities in product development, design enhancements, predictive maintenance, and unparalleled personalization.

During the product development phase, engineers can leverage digital twins to assess the feasibility of their plans, conduct user testing, and optimize manufacturing processes. Here’s a hypothetical example of how it might work:

- Workflow optimization. Digital twins enable the creation of virtual models that represent physical objects, systems, and real-time processes. They can depict equipment status, behavior, material flow, assembly processes, and other production parameters. As a result, enterprises can analyze and optimize production processes, enhance production efficiency and quality, and reduce costs.

- Problem Prevention. The technology helps monitor equipment operation in real-time and predict possible failures or problems. Monitoring parameters such as temperature, pressure, vibration, and others can detect anomalies and take predictive maintenance measures, preventing accidents and increasing equipment reliability.

- Productivity increase. Digital twins allow simulations of various production process scenarios. They can use data from actual equipment, analyze different process settings, optimize resource allocation, and predict results. It helps businesses make informed decisions and improve productivity and efficiency.

You can also use digital twins to train staff and process simulations without the risk of equipment damage or production downtime. The technology provides visualization and interactive tools to train new employees, improve skills, and test new ideas and ways of working.

For example, Chevron, the largest energy company in the US, is already implementing digital twin technology to explore oil fields and optimize refinery operations. In this way, the company expects to save millions of dollars to maintain its facilities.

Siemens also sees digital twins as essential in modeling and prototyping new products. The company aims to expedite the market launch of new products.

2. Healthcare

In the healthcare industry, digital twins significantly accelerate processes and empower information and product development.

Digital twins open up a new space for testing new drugs or medical devices without putting people at risk. The new technology will help medical staff make informed decisions and better communicate with clients. Here are just some of the possibilities of digital twins in the medical field:

- Digital twins allow the creation of virtual patient models that include health information, genetic data, and medical history. Personalized diagnostics will facilitate diagnosis and help to understand the best treatment options.

- The technology can help simulate medical procedures such as surgery. Thus, the staff will be able to train better and create optimal treatment plans.

- Medical specialists can monitor patients’ health in real-time thanks to the combination of the digital twin and IoT. Therefore, the technology can facilitate diagnosis and treatment and significantly speed up decision-making.

- Digital twins enable medical professionals to utilize data for health research purposes. For instance, data can be leveraged to predict the spread of diseases, evaluate treatment effectiveness, identify patients at high risk for specific diseases, and more.

One notable example of the application of digital twins in medicine is the HeartModel developed by Philips. This program generates virtual representations of hearts based on 2D ultrasound images. Consequently, medical professionals can create digital twins of patients’ hearts to study them in detail and gain valuable insights.

Also, during the COVID-19 pandemic, experts used digital twins to optimize the work of hospitals and staff. We can use this approach in the future for more minor problems to make medicine more accessible and practical.

3. Architecture and construction

In the field of architecture, digital twins have emerged relatively recently. It is primarily because architects traditionally adhere to established design rules when creating buildings. However, digital twins allow architects to explore new possibilities and go beyond conventional approaches:

- Architects can model various objects and engage in experimental design by utilizing digital twins. The capabilities offered by this technology enable the creation of unique designs and the exploration of innovative ways to overcome existing restrictions.

- Architects can leverage digital twins to test their projects and gain insights into how the design will align with the future user experience. Additionally, digital twins facilitate generating new solutions that optimize space utilization.

Beyond the design phase, digital twins greatly assist in project implementation.

Construction teams can streamline their work processes by utilizing digital models. These models enable project progress tracking, task completion verification, and resource management. Consequently, construction time and costs are reduced, and schedule adherence and work quality are improved.

4. Logistics

Indeed, logistics is an area where machines and advanced technologies such as artificial intelligence and neural networks excel. Our previous articles explained how these technologies could optimize logistics processes.

Digital twins can also play a vital role in the logistics industry. They serve as invaluable tools for testing new concepts and products, simulating changes in the supply chain, and predicting potential problems. By creating virtual replicas of real-world logistics systems, digital twins enable companies to assess the impact of changes, identify bottlenecks, and make informed decisions to enhance efficiency and mitigate risks.

Here are some examples of optimizing logistics with digital twins:

- Digital twins enable the creation of virtual models for supply chains, facilitating the seamless monitoring of goods’ journey from production to final delivery to the end consumer.

- The technology helps to track the location and condition of goods in real-time during transportation. In this way, the digital twin prevents the loss or damage of goods and allows you to respond quickly to problems or delays.

- Digital twins allow you to analyze and simulate various routes and logistics operations options. Using data on traffic, cargo volumes, time constraints, and other factors, logistics companies can optimize delivery routes, choose the best modes of transport and improve resource utilization.

- You can better analyze and model demand and customer needs' data to minimize the risk of shortages or surpluses.

- Digital twins help optimize warehouse space used by visualizing the location of goods.

- By harnessing digital twins, businesses can enhance customer service by attaining heightened visibility and control over their logistics operations. This approach, in turn, enables logistics companies to furnish customers with precise and up-to-date delivery status information, proactively notify them about potential delays, and provide a more comprehensive array of adaptable and personalized services.

There are many ways to use digital twins in logistics, you only need to choose an existing one or create your own.

5. Retail

Large and small businesses can turn to digital twins to improve their sales performance. For example, retail stores can model the mood and behavior of customers and try out strategies that will lead to better product delivery.

Moreover, with the aid of IoT sensors, real-time tracking of the in-store experience becomes feasible. Additionally, digital twins can generate customer traffic maps, comprehend the target audience, and research purchasing patterns. Store owners now possess novel avenues for product tracking and optimizing queues.

In essence, the potential of digital twins knows no bounds, limited solely by one’s imagination. It’s foreseeable that this tool will soon become an indispensable necessity for a vast majority of businesses.

But what does it take to start using a digital twin and get all these benefits?

Things to consider before creating a digital twin

To start using the digital twin, you must carefully prepare at least three points.

1. Data security

As per a Gartner study, it’s projected that 75% of digital twins utilizing IoT by 2023 will incorporate five specific types of endpoints. However, it’s crucial to note that the endpoints may exceed this estimate, and each presents a potential security vulnerability.

Hence, before implementing a digital twin system, it becomes imperative to prioritize enhancing security protocols. This approach includes focusing on robust data encryption measures, meticulous management of access privileges, and eradicating existing device vulnerabilities.

2. Data setting

To create an accurate and comprehensive digital twin, a wide range of data sources is essential. It is sensor data, measurements, images, location data, equipment health data, and other relevant information. Identifying the necessary data for constructing a precise model is crucial. Equally important is ensuring the quality of the data, where your role plays a significant part.

Implementing measures such as flow control and the exclusion of unreliable information becomes crucial to accomplish this goal.

3. Team preparation

Ensuring employees working on digital twins possess the necessary skills and tools is paramount. Users of this technology must embrace the new work methodology and be prepared for potential integration challenges.

Establishing clear and well-defined goals is crucial before implementing a digital twin. Equally important is selecting the appropriate technology and configuring monitoring algorithms. These measures enable businesses to elevate their operations to new heights while minimizing the risks of encountering problems.

Although the concept of digital twins is relatively new and unconventional, numerous companies are already contemplating their adoption. This way is primarily due to the immense potential this technology holds. Seasoned CEOs are inclined to embrace it early on, as they recognize the multitude of benefits it can bring to their organizations.

The potential of digital twins: Summing up

The future of digital twins is optimistic and dynamic. With the rapid advancement of technologies like the Internet of Things (IoT), artificial intelligence (AI), data analytics, and cloud computing, digital twins are poised to witness widespread adoption and increased demand across various industries and fields of activity.

It’s even conceivable that each individual might possess their own digital twin in the future, though this possibility is contingent upon the specific context and application. Digital twins within the personal realm can be depicted as virtual models encompassing a person’s information, such as their health, preferences, and interests. These models can be leveraged to personalize services, enhance healthcare, offer guidance, and facilitate decision-making.

Nevertheless, it’s crucial to emphasize that ownership and control over one’s digital twin should firmly rest in the hands of the individual. Ensuring data privacy and security stands as a vital aspect in the advancement of personal digital twins. Individuals ought to possess the right to choose which data is collected, how it’s utilized, and with whom their digital twin is shared.

Conclusion

In conclusion, digital twins have the potential to usher in a new era of industrial transformation. This technology not only simplifies processes for companies but also paves the way for developing innovative and superior products and services for consumers.

As time progresses, digital twin technology will continue to evolve and advance. If you recognize the potential benefits of employing digital twins in your business operations, consider adopting this technology. Embracing digital twins today can give your business a competitive edge and position you for future success.

With Vilmate by your side, you'll have a multidisciplinary team of experts ready to assist you in creating your digital twin.

Our skilled programmers will handle the technical aspects, developing the software architecture and implementing the required functionalities. Our talented designers will ensure an intuitive and visually appealing user interface for your digital twin.